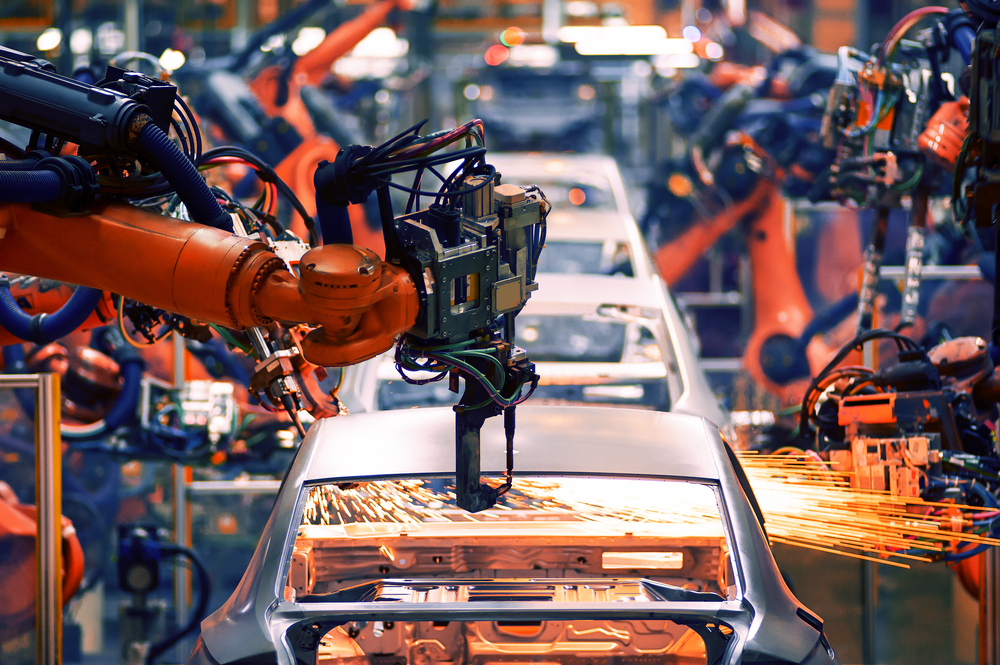

Gone are those days when marking was one of the difficult things to handle especially when it comes to the Automotive industry. These days with the invention of technology, marking has become easy.

Technology like Automotive Part Marking Technology and other Industrial Marking Solutions has made things much easier. These days you can easily find a Portable Marking Machine and other Industrial Engraving and Marking Systems that let you mark with precision even on the smallest part.

But when it comes to the Automotive Industry Marking Solutions, it is not something that you can take for granted. Marking not only aids in differentiating genuine parts but also makes the process of replacement easy at later stages.

This is why you cannot neglect the role of the Automotive Part Marking Machine. The mark must be so detailed and fine that it must withstand wear and tear.

When it comes to the automotive industry, the marking is required on

Engine Parts: Gear, Engine block, Cylinder, Pistons, Piston Rod, Crankshaft, Camshaft, and so on.

Fuel Supply System: Fuel Pump, Alternator, Injection System, Starter, Air Cleaner, Radiator, Water Case.

Chassis: Doors, Car Frames, Body Panels, Chassis, IN Number.

Gear Case: Gears, Body Valve, Bearings, Shaft.

Power and Steering System: Brake Components, Wheels, Transmission Part, Driver Shaft, Shock Absorber, Suspension Arm.

Exhaust System: Exhaust System, Silencer, Muffler, Manifold, Catalyst Converter, Particulate Filter.

Interior Components: Air Conditioning, DashBoard, Seat belt, Cigarette Lighter, and others.

Sensors and Switch: Multi-Function plug, Heating Control, Oil Pressure Sensor, Air Flow Sensor

Lighting: Fog lamp, Head Lamp, Taillight.

Now you must be clear with the requirements of marking on various parts in the automotive industry. Well, let us have some tips regarding marking now.

1. When it comes to marking, durability plays a crucial role. You must be clear about what you are looking for. Basically, there are 3 types of laser marking.

- Anneal

- Etch

- Engrave

All three carry a different level of durability. So you must be clear with the level of durability you are looking for.

2. It is crucial to take the material into account. This is so because there is a wide variety of materials that are used in the automotive industry. You must know, not all materials respond to every type of mark. It is good to go with that material that is capable enough to absorb the laser’s wavelength.

3. You must focus on target production throughput. It is good to understand the schedule and to ensure that marked parts are produced in sufficient volume and within the stipulated time period.

4. If you are going with annealing, you must know that it is slow. On an average basis, it remains at 10 inches per second. So be prepared for it. Moreover, it is good to do annealing on the material that contains carbon.

5. When it comes to etching, some amount of material is always removed in the process. So it is advised to control what is wasted in the process. It is done on some organic material like Acrylonitrile Butadiene Styrene (ABS) plastic, rubber, foam, and so on. This is what you need to take care of. This is so because if you apply too much power during the process of marking on ABS, the plastic will melt.

6. When it comes to engraving, here also some material will be removed. So you are required to take control. Moreover, you must know that all metals can be engraved but when it comes to marking on highly reflective metals, it is going to be a challenge. So be prepared for it.

7. It is good to be clear about marking speed. This will let you choose the marking machine as per your requirement. You must also be clear with the depth of the engraving. It is good to discuss your requirements with Portable Engraver Supplier to get the best.

8. You must discuss in advance the after-sale service or technical support from the buyer before purchasing a marking machine.

9. It is good to go with abrasion-proof laser marking when you have to mark on tires.

10. Do not forget to follow guidelines regarding marking for various automotive components. Then it doesn’t matter whether these guidelines are general guidelines or are related to a specific machine. This will let you get the best.

Conclusion

When it comes to the automotive industry, there are many Industrial Engraving and Marking Applications. So it becomes crucial to know your demands and then buy a specific machine that will serve the purpose without putting a load on your pocket. Apart from this, you are required to follow marking tips. This will make your task much easier and will let you use your machine for a longer duration.